Sidebar

Wigram Airforce Museum

The Challenge

RNZAF Wigram ceased to be an operational aifield some years ago and (mostly) has been redeveloped as a mix of residential and commercial properties.

The RNZAF still retains a presence however in the form of the RNZAF Museum.

The Mueum faced two issues; the first in the form of a very restrictive resource consent for the use of coal for central heating, and the second, the expansion of the heating system to include the older and (as yet) unheated exhibition hall.

Main Features

- A coal fired sectional boiler aproximately 30 years old.

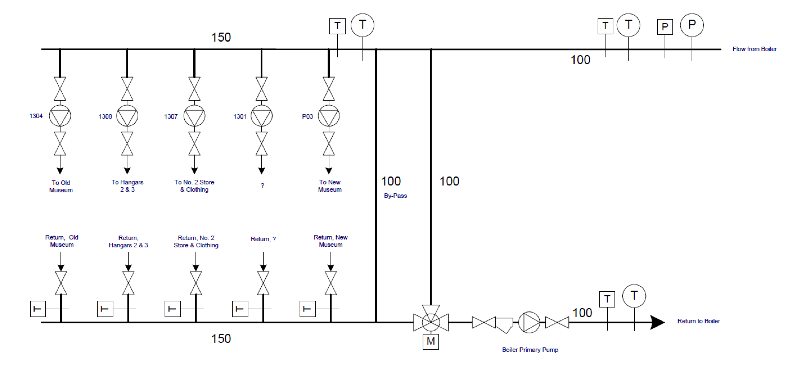

- A low temperature hot water distribution sysem to both the older part of the museum and the recent major expansion.

- An application to ECan (the territorial authority) to expand the limits of the Resource Consent was overlooked when the museum was expanded, with the consequence that it was burning more coal than permittied by its consent conditions.

- A distribution system which had been expanded twice since the original construction of the boilerhouse without understanding the design and inherent limitations of the original installation.

- Boilerplant which was not controlled by the main museum control system.

- Boilerhouse controls and equipment which had not been updated since their installation almost 30 years before.

The Response

The initial response was an energy audit to see if it might be possible to reduce the Museum's coal usage to a level which allowed compliance with the terms of the Resource Consent.

A number of opportunities were identified that might just enable the Consent Condtions to be met. It would however be a very close run thing.

In the event, whilst improvements were made, the consent conditions could not be reliably met.

The Energy Audit made clear that the long term sure-solution would be to change the boiler fuel from coal to either wood pellets or wood chip.

A Concept Report was commissioned by the NZDF which confirmed both the technical and economic feasibility of the solution.

A subesequent Detailed Design & Specification was then let to provide a basis for tendering out and installing the requisite works.

The Works

The Works

The works broke into four sections;

- An application for a new Resource Consent,

- Redesign to eliminate the existing problems,

- Refurbishments to upgrade the boiler and ancilary plant to currnent stadnards, and

- Conversion to woodpellet or chip ("biomass") operation.

After considerable effort on the part of Bryn Martin in conjunction with Air Consenting speciallist Don Pullen a 30 year consent to burn unlimited ammounts of biomass fuel was granted, eliminating a serious limit on the Museums future operations.

The pipework, pumps, and valves were replaced and re-arranged to eliminte the artificial restrictions which had been built into the systm by past additions and alterations. Now for the fist time since the 1990's all of the museum circuts are able to draw as much central heating water as they need.

The electrical switchpanels have bene replaced, the bulding management system expended to control all of the boilerhouse, and the boiler control panel replaced with the latest version incoporating all of the features required to handle biomass.

At the end of the 2016 heating season the changeover to biomass willl be completed, and very unsuaually a full particulat monitoring system will be fitted to th boiler flue, logged in real time by the BMS

For more Information on this or any other project or service please contact Brian Anderson or Tim Allan.